Material Testing Laboratory performs:

- a) metallographic examination of steel and cast iron :

- macrostructure assessment

- microstructure assessment use a metallographic microscope

b) tests of mechanical properties of steels and cast irons :

- static tensile tests at ambient temperature

- toughness examination Charpy method at ambient temperature and below zero

- hardness measurements by Brinell, Vickers and Rockwell methods

- determination of the thickness of hardened layers by the method of hardness distribution

The group of Analytical Laboratories performs:

- Study of materials for production and end product,

- Control of the production process,

- Product research,

- Analysis of the chemical composition of the iron cast,

- Analysis of the pickling solutions and flux,

- Analysis of the composition of the atmosphere in the iron furnaces.

Environmental Protection Laboratory performs:

- Physico – chemical analysis of water and wastewater.

Laboratory Supply of Materials and Strength performs:

- Study materials and tools provided for production,

- Research supplies of scrap steel,

– tensile strength R m,

– elongation A,

– hardness HB,

– strength impact, - Testing the strength of electrical power equipment .

Metallurgical Laboratory:

Determines the microstructure and strength of cast samples from the finished products .

Performs photographic documentation of all metallographic specimens .

It describes the structure of the species tested cast iron.

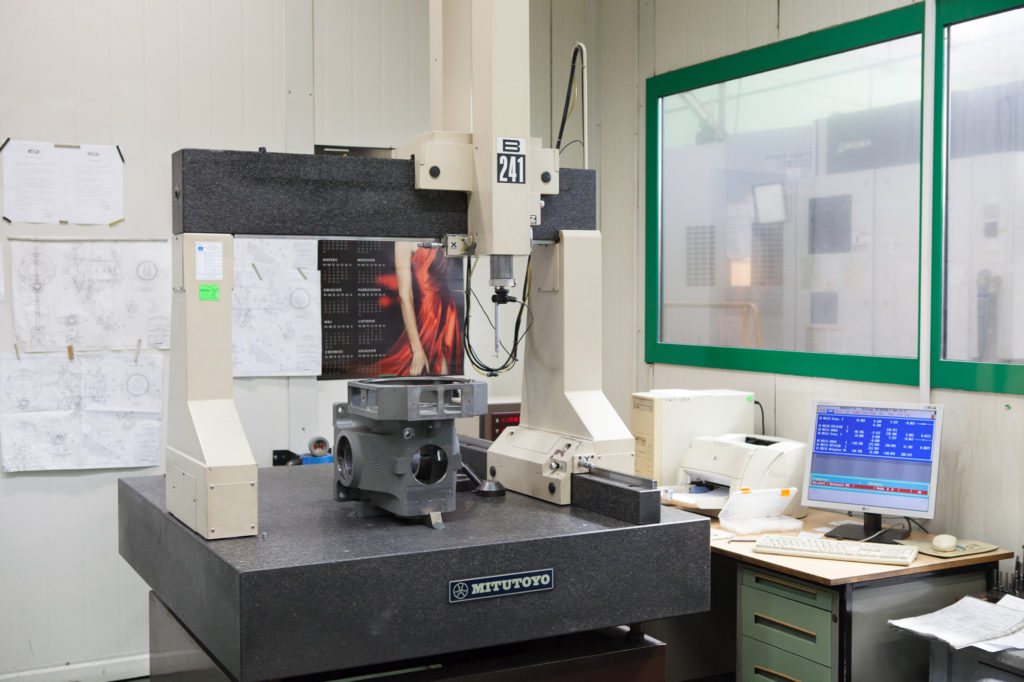

Measurements Laboratory performs:

- measuring and testing equipment control – measuring,

- measurements of the supply of equipment for the production,

- measurements of foundry and machining , new or recycled,

- measurement products in accordance with the terms agreed with the customer acceptance and control measurements in all dimensions,

- control measurements for the thickness of zinc coating.